E-mail-formatfejl

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheder

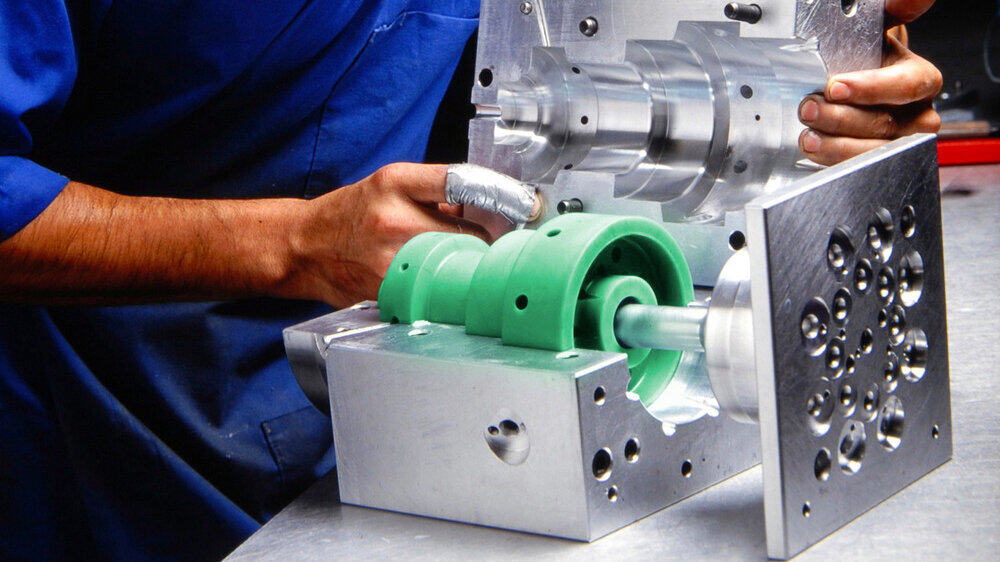

wax mold casting,cast iron wax,lost wax carving

Precision casting is a special casting. The parts obtained by this method generally do not need to be machined, such as wax mold casting, die casting, etc. Precision casting is a casting method relative to the traditional casting process. It can obtain relatively accurate shape and high casting accuracy. So, what is die casting and lost wax casting?

What is die casting and wax mold casting?

Die casting is a metal casting process characterized by the use of a mold cavity to apply high pressure to molten metal. Molds are usually machined from stronger alloys, a process somewhat similar to injection molding.

Lost wax casting is one of the casting methods for making metal products and is often referred to as precision casting. Its characteristic is to use investment materials to make investment parts and form modules, and then coat multi-layer refractory materials on the surface of the modules. After drying and curing, the models are heated to dissolve the abrasives, and after high-temperature sintering, they are poured into molten metal to condense. Then the lost wax carving is obtained.

Both processes belong to precision casting, but they are very different and are two completely different casting processes.

Lost wax casting v.s. die casting, what is the difference between these two processes?

👉Inputs for production costs:

Die casting: The biggest disadvantage of die casting is the high cost. Die casting machines as well as molds and mold-related components are expensive relative to other casting methods. Therefore, it is more economical to produce a large number of products when manufacturing die castings.

Lost wax casting: The investment of cast iron wax is small, and the whole process can be replaced by manual or automated equipment, but compared with die casting, even if a full set of automated equipment is used, the cost of lost wax casting is 4-6 times lower than that of die casting.

👉Differences in application areas:

Die casting: This process is only suitable for metals with high fluidity, and the casting mass must be between 30 grams and 10 kilograms.

Lost wax casting: Using the cast iron wax method for precision casting can not only achieve mass production, ensure the consistency of castings, but also avoid the stress concentration of residual knife lines after machining.

👉Advantages and disadvantages:

Die casting: Due to the huge input cost, it is more economical when mass production is required. In normal die casting, there will always be voids in the last batch of castings cast. Therefore, no heat treatment or welding can be performed, because the gas in the gap will expand under the action of heat, causing internal micro-defects and peeling of the surface. Die castings usually have defects such as sand holes and burrs, and the amount of post-processing is relatively large.

Lost-wax casting: Because lost-wax castings have high dimensional accuracy and surface finish, machining work can be reduced, but only a little machining allowance can be left on the parts with higher requirements, and even some castings are only left for grinding, polishing allowance, without machining. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing time, and greatly save metal raw materials.

Any techniques have been tested for thousands of times, and each of them has been facilitating and beautifying our lives. For more information, please feel free to contact us, we are glad to serve you.