E-mail-formatfejl

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheder

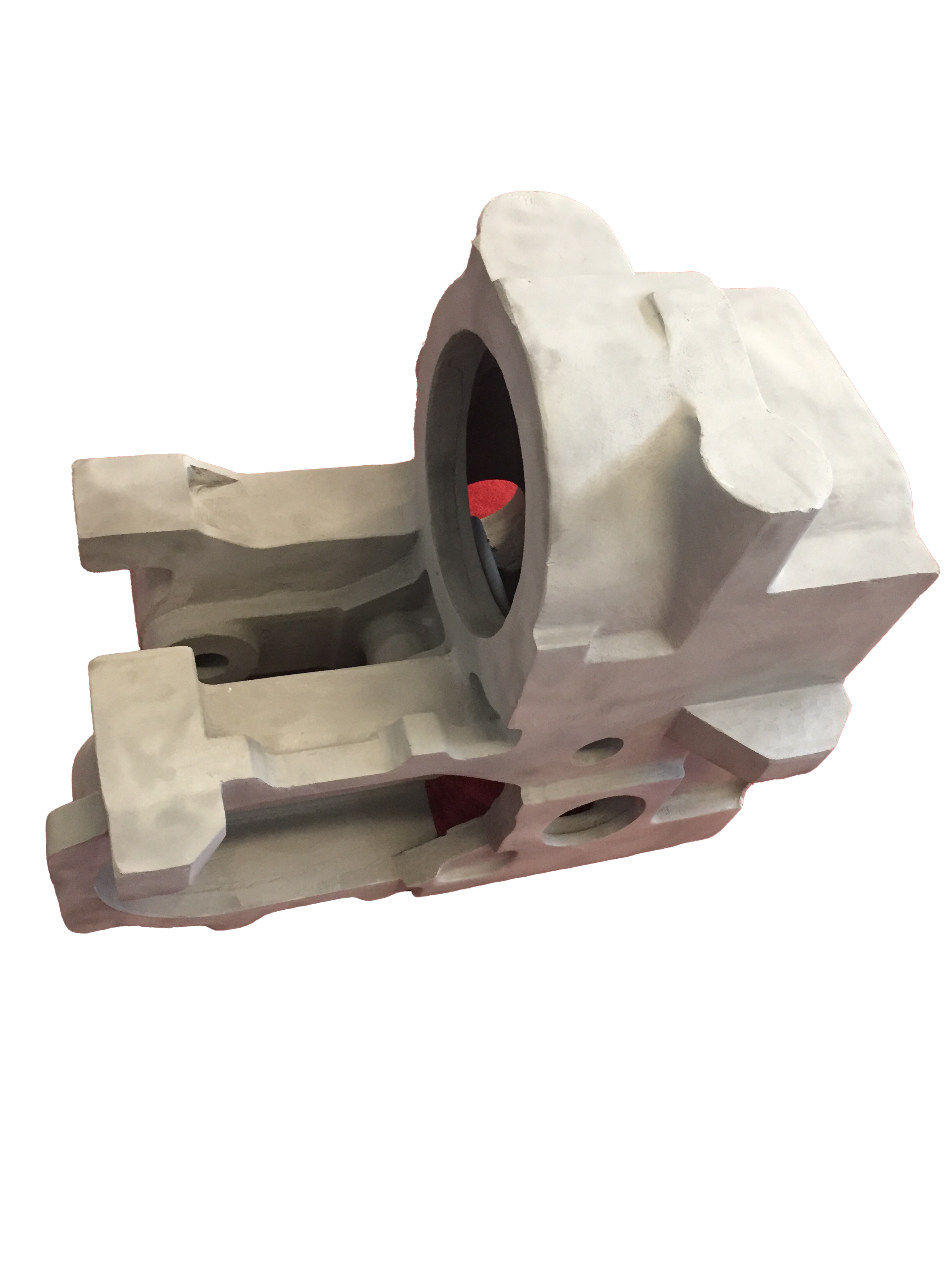

The Application of Filter in Aluminum Alloy Die-Casting Production

In rare metal production manufacturing, aluminum alloy is widely very easy to air oxidation is another industry headache problem, whether aluminum, copper or other aluminum alloys are very similar. At this stage, the choice of reasonable aqueous solution removal and slag gr `anulation and circulation system degassing method and other metal materials to solve the technicality, the basis has long been able to deal with the relevant problems.

However, in the aluminum alloy die casting forging manufacturing, when the shape memory alloy from the holding furnace into the concave die, there is still such a problem, that is, here a link appears all the flow field is caused by thin oxide skin. This shortcoming is not only not easy to "heal" again, but also as a weak link in the aluminum alloy die casting, and often because of the leakage gap between the two walls caused by the unsuccessful pressure test.

The application of filter in aluminum alloy die-casting production

Filtering devices are widely used in the rare metal casting industry for many years. However, it is well established that the filtering device must have the following two independent characteristics: the ability to remove the residue trapped in the metal material; to ensure a stable flow of metal material, and no vortex into the concave mold.

As soon as the shape-memory alloy flow reaches the surface of the foam filter channel, there is a transient stagnation, which generates an abundant condensation. This working pressure is caused by the metal material level difference in the direct pouring nozzle, and once created, the metal material flow is repaired as if the filtering device would not have been pressed at all.

The flow field in the pouring system software is mostly generated in locations such as the straight inlet nozzle and the front end development of the straight sprue bar. If a foam filter is placed across the straight sprue bar, the metal flow will be stopped and the pouring will be stable when the straight sprue is filled, thus avoiding the generation of oxide. The foam filter is a filter with such characteristics.

Applying this kind of filter device, it is not afraid of the aluminum alloy die casting being oxidized by the air immediately in the whole process of generation, and it is a very reasonable way.

How to choose the filter in the aluminum die casting process

The following issues need to be noted for filter selection:

Filter import and export diameter

In principle, the import and export diameter of the filter should not be smaller than the import diameter of the matching pump, but generally the same as the import pipeline diameter.

For example, if the pipeline is DN100, the caliber of the VTON filter should generally not be lower than DN100.

Nominal pressure selection

Determine the pressure level of the filter in accordance with the highest possible pressure of the filter pipeline. For example, if the pressure of the pipeline is PN25, the VTON filter should choose PN25.

Selection of the number of holes

The selection of the number of filter holes mainly takes into account the particle size of impurities to be intercepted and is based on the process requirements of the media flow. The size of particle size that can be intercepted by various specifications of the screen is shown in the following table "Screen Specifications". General water import filter mesh is 40-80 mesh, VTON VTON steam import filter mesh is 100-200 mesh, and other gas VTON VTON import filter mesh according to the customer's requirements for gas precision selection.

Filter material

The material of the filter is generally chosen to be the same as the material of the connected process pipeline. For different service conditions, filters made of cast iron, carbon steel, low alloy steel, or stainless steel can be considered. For corrosive media, stainless steel or fluorine lining and rubber lining should be selected.

Filter resistance loss calculation

Water filter, in the general calculation of the rated flow rate, the pressure loss of 0.52 ~ 1.2kpa.

Conclusion

For more information about a hot chamber die casting machine,in hot chamber die casting machine,pressure die casting machine, we are glad to answer for you.