E-mail-formatfejl

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheder

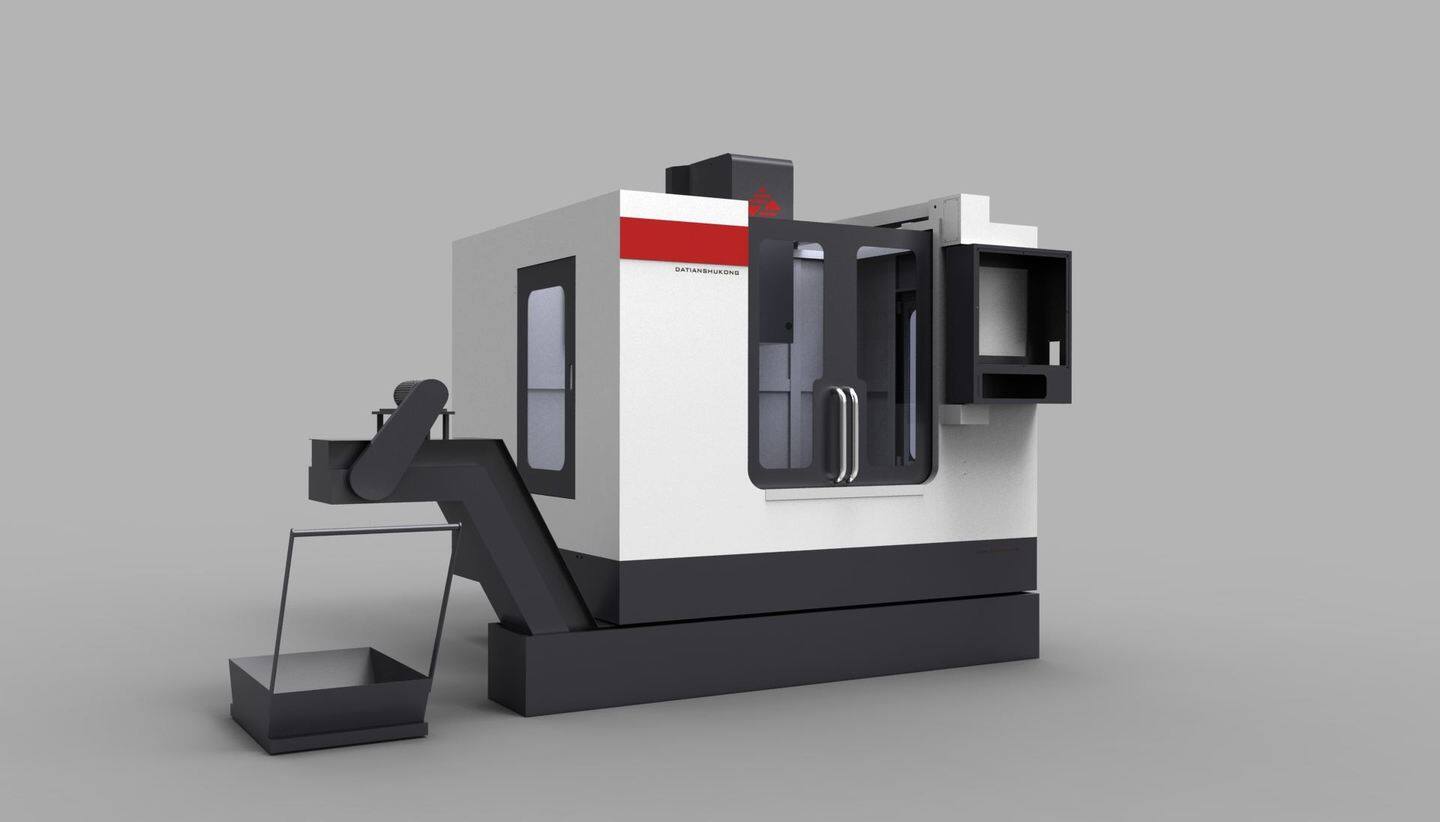

Maintenance of all parts of CNC milling machine

Maintenance of spindle system of CNC milling machine

- cleaning of spindle taper hole

The taper contact between the spindle taper hole and the tool shank keeps the coaxiality between the tool and the spindle center. If the spindle taper hole is not clean, it will cause the deflection and misalignment between the spindle and the tool center, which will affect the accuracy of the workpiece. Therefore, it is very important to keep the spindle taper hole clean. Before installing the cutter, clean it with compressed air and remove the dirt from the taper hole.

- regularly clean the spindle components

Clean the dirt on the spindle fan every three months.

- maintenance before stopping machining center

For machining centers that have not been used for a long time, they must be painted first to prevent main components such as the main shaft from rusting.

- spindle structure

It is a hollow shaft structure, and the front end is provided with a taper hole, which is matched with the tool handle; The rear end is equipped with an automatic tool clamping mechanism.

There are two kinds of common spindles: the spindle unit composed of belt drive and gearbox and the electric spindle. Motorized spindle is to install the motor directly in the spindle, and the motor is connected to the spindle to directly drive the tool movement.

- automatic tool clamping mechanism

It is composed of knife handle, collet, butterfly spring, piston, and cylinder. The air cylinder is supplied by the air compressor.

- end face key

An end face key is installed at the lower end of the spindle, which is matched with the tool shank for driving torque. The taper of the tool shank and the taper in the lower hole of the spindle only play a centering role and cannot transmit torque.

- automatic chip removal device

It refers to the automatic removal of chips and dirt in the spindle hole by compressed air to ensure the correct positioning of the cutter bar.

Maintenance of feed system of CNC milling machine

- driving device

It is divided into a stepping motor drive and an AC servo motor drive. Stepper motor drive has no position feedback, and it's precision and load capacity are poor. It is only used for economical CNC machine tools. AC servo drive motor has position feedback, which is the development direction of the feed drive.

- position detection device

It is only used in an AC servo control system to detect the speed and phase angle position of the servo motor, which is called a closed-loop or semi-closed-loop detection device.

- mechanical transmission mechanism

- Gear transmission - decelerates through gear transmission.

- Synchronous belt transmission - the synchronous belt combines the advantages of V-belt transmission and gear transmission, and the transmission is accurate and stable.

- Coupling - the connection between the motor and the ball screw.

- Ball screw transmission - the traditional sliding friction transmission of the ball screw is replaced by the rolling friction transmission of the ball screw, which has high transmission accuracy, no reverse transmission clearance, and sensitive and accurate transmission.

- Guide rail - divided into hard rail and wire rail. Generally, rigid rails with plastic plates are used.

- Executive part - the workbench. There are three T-shaped slots on the workbench to fix the flat tongs or directly install the workpiece.

Maintenance of CNC machining center tool magazine

- hat-type magazine without the manipulator

The structure is simple, the cost is low, and it is easy to control. The tool outside the tool magazine and the spindle tool sleeve are on the same axis. Generally, the tool change process is controlled by pneumatic or hydraulic pressure.

- disc magazine with manipulator

The tool magazine is installed on one side of the column of the machining center. The tool to be changed is rotated to the lower part of the disc tool magazine according to the instruction requirements and converted to a vertical position. The manipulator is used to complete the actions of tool extraction, tool change, tool installation, and reset.

Make a purchase of multi spindle cnc milling machine, mini cnc milling machine for metal, best mini cnc milling machine from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.