E-mail-formatfejl

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheder

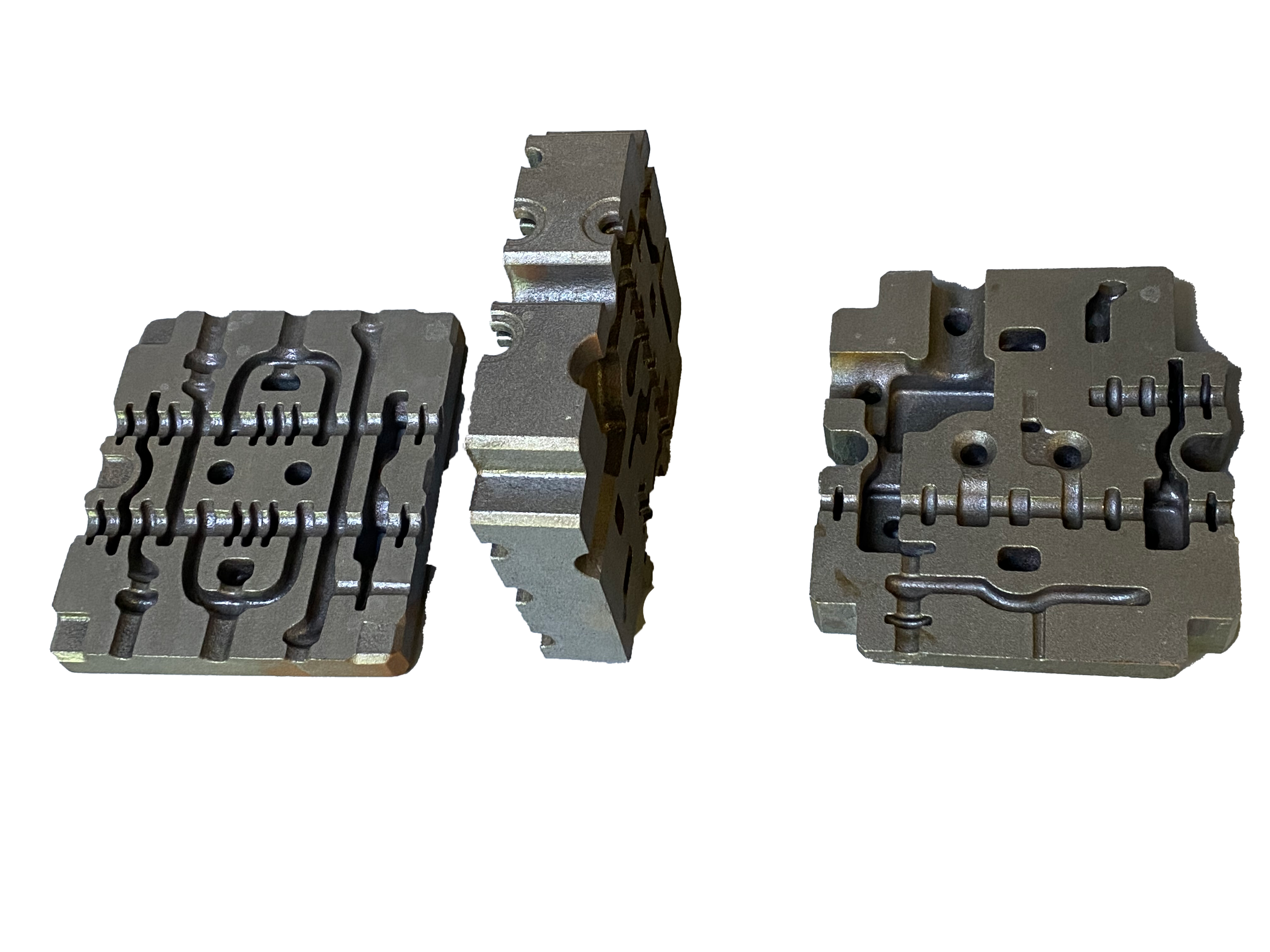

Difference between Cast Steel and Cast Iron

The essential difference between cast iron and cast steel lies in the difference in chemical composition. In engineering, it is generally considered that iron with carbon content higher than 2% and steel with carbon content lower than this value. Due to different compositions, the microstructure and properties are also different. Generally speaking, the plasticity and toughness of cast steel are good, showing good elongation, reduction of area, and impact toughness. The mechanical properties of cast iron are hard and brittle.

Although they are both iron-carbon alloys, they have different metallographic structures after crystallization due to the different percentages of carbon, silicon, manganese, phosphorus, sulfur, and other chemical elements, showing many differences in mechanical properties and process properties.

For example, in the casting state, the elongation, reduction of area, and impact toughness of cast iron are lower than those of cast steel; The compressive strength and shock absorption of cast iron are better than that of cast steel; The liquid fluidity of gray cast iron is better than that of cast steel, and it is more suitable for thin-wall castings with complex structure; In the bending test, cast iron is a brittle fracture and cast steel is bending deformation. wait. Therefore, they apply to cast machine parts with different requirements.

How do distinguish cast iron and cast steel in actual production and life?

- Cast steel is bright. Cast iron is dark and gray. The gray iron in cast iron is different from nodular iron. Nodular iron is brighter than gray iron.

- Cast steel is very dense, and particles are generally invisible to the naked eye. Both gray iron and ductile iron can see particles, and the gray iron particles are larger.

- The impact of steel castings is "just" and different from that of cast iron castings.

- Gas cutting. The surface of steel castings is rough, and the riser and gate areas are large, which must be removed by gas cutting. The gas cutting of nodular cast iron is continuous.

- The toughness of cast steel is close to that of steel plate, while that of nodular cast iron is slightly inferior. The thin-walled parts can reach 20-30 degrees of bending, and the gray cast iron has no toughness.

- Difference between Ma Steel and ductile iron. The hardness, wear-resistance, and tensile strength of nodular cast iron are much higher than those of Ma steel, and the tensile strength can reach 1000MPa. Nodular cast iron can be used as various high-strength structural parts such as engine crankshaft and gear. By listening to the sound, we can distinguish between Ma Steel and nodular cast iron. The sound of Ma steel is very sharp and short; Ductile iron has a loud sound and long echo. Although they are both iron-carbon alloys, they have different metallographic structures after crystallization due to the different percentages of carbon, silicon, manganese, phosphorus, sulfur, and other chemical elements, showing many differences in mechanical properties and process properties. For example, in the casting state, the elongation, area reduction, and impact toughness of cast iron are lower than those of cast steel, and the compressive strength and shock absorption performance of cast iron are better than those of cast steel. The liquid fluidity of gray cast iron is better than that of cast steel, and it is more suitable for thin-wall castings with complex structures. In the bending test, cast iron is a brittle fracture and cast steel is bending deformation, and so on. Therefore, they apply to cast machine parts with different requirements.