E-mail-formatfejl

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheder

Classification of Cast Iron

Cast iron is an iron-carbon alloy with a carbon content greater than 2.11% (generally 2.5 ~ 4%). It is a multi-element alloy with iron, carbon, and silicon as the main constituent elements and contains more manganese, sulfur, phosphorus, and other impurities than carbon steel. Sometimes, to improve the mechanical properties or physical and chemical properties of cast iron, a certain amount of alloy elements can be added to obtain alloy cast iron.

According to the different forms of carbon in cast iron, cast iron can be divided into

- white cast iron

Except for a small amount of carbon dissolved in ferrite, the rest of the carbon exists in cast iron in the form of cementite, and its fracture is silver white, so it is called white cast iron. At present, white cast iron is mainly used as raw material for steelmaking and blank for producing malleable cast iron.

- grey cast iron

The carbon content of gray cast iron is high (2.7% ~ 4.0%), the carbon mainly exists in the form of flake graphite, and the fracture is gray, which is called gray iron for short. Low melting point (1145 ~ 1250 ℃), small shrinkage during solidification, compressive strength and hardness close to carbon steel, and good shock absorption. Due to the existence of flake graphite, the wear resistance is good. Good casting performance and machining. Used for manufacturing machine tool beds, cylinders, boxes, and other structural parts. Its brand is followed by "HT" with two groups of numbers. For example HT20-40 (the first number represents the minimum tensile strength and the second group represents the minimum bending strength).

According to the shape characteristics of graphite, grey cast iron can be divided into

- ordinary grey cast iron.

The graphite of ordinary gray cast iron is flaky and consists of graphite and matrix. The matrix can be ferrite, pearlite, or ferrite plus pearlite, which is equivalent to the structure of steel.

- malleable cast iron.

The graphite of malleable cast iron is flocculent, which is obtained after annealing of white cast iron. The graphite is flocculent, which is called ductile iron for short. It has uniform microstructure and properties, wear resistance, good plasticity, and toughness. It is used to manufacture parts with complex shapes and can bear a strong dynamic load.

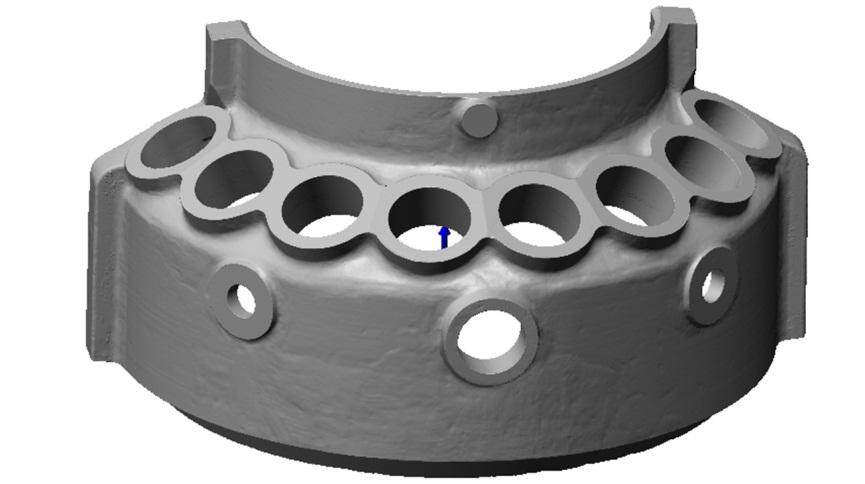

- nodular cast iron.

The graphite of nodular cast iron is spherical. Gray cast iron is obtained by spheroidizing molten iron, and the precipitated graphite is spherical, which is called nodular iron for short. All or most of the carbon is spherical graphite in a free state, and the fracture is silver gray. It has higher strength, better toughness, and plasticity than ordinary gray cast iron. Its brand is represented by "QT" followed by two groups of numbers, for example, qt45-5 (the first group of numbers represents the minimum tensile strength and the second group of numbers represents the minimum elongation). It is used for manufacturing internal combustion engines, auto parts, agricultural machinery, etc.

- vermicular graphite cast iron.

The graphite precipitated from the hot metal of gray cast iron is vermicular. The mechanical properties are similar to that of nodular cast iron, and the casting properties are between that gray cast iron and nodular cast iron. Used to make automobile parts.

Make a purchase of coated cast iron, kichly cast iron, mini cast iron skillets from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.