E-mail-formatfejl

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheder

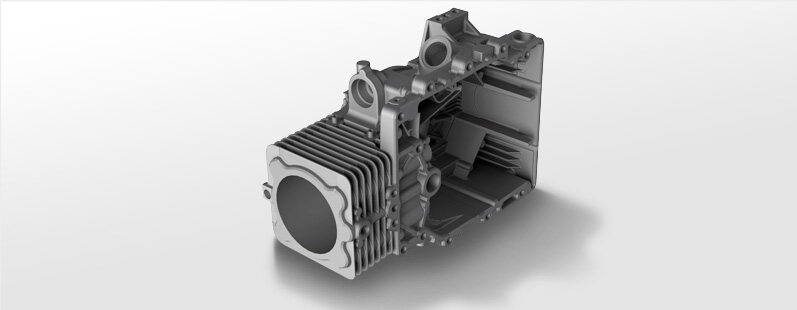

aluminum die casting parts manufacturers

If the aluminum dies casting parts are not well prepared in the casting process, lack quality awareness, and there are great problems in the casting process, it is very easy to cause cracks in the aluminum die casting parts.

Once cracks appear in the castings, it will cause huge losses to the casting enterprises. Therefore, the foundry must carefully analyze the causes of cracks in the castings and summarize the experience and lessons, Only by taking effective improvement measures can cracks in aluminum casting parts be prevented.

-

Improving the structure of aluminum die casting parts

The wall thickness shall be uniform, and transition fillets shall be made at the corners to reduce stress concentration. The spokes of wheel aluminum die casting parts can be made into bending shape when necessary.

-

Improving the melting quality of alloy materials

Refining and degassing processes are used to remove oxidation inclusions and gases in molten metal. Control the content of harmful impurities and adopt a reasonable smelting process to prevent cold cracks.

-

Adopt correct casting process measures

The simultaneous solidification of aluminum die casting parts is not only conducive to the prevention of hot cracks, but also the prevention of cold cracks. Reasonably set the position and size of the pouring and riser to make the cooling speed of all parts of the aluminum alloy die casting part as uniform as possible and reduce the tendency of cold crack.

Correctly determine the residence time of aluminum alloy dies casting parts in the sand mold. The sand mold is a good thermal insulation container, which can further homogenize the temperature at the thicker and thinner parts of aluminum alloy die casting parts, reduce the temperature difference between them, reduce the thermal stress and reduce the tendency of cold cracks. Prolong the residence time of aluminum alloy die casting parts in the mold to avoid large internal stress and cold crack caused by premature unpacking in the aluminum alloy die castings.

Increasing the concession of sand mold and sand core, removing the pressure box iron, and loosening the sandbox fastening device as soon as possible after the solidification of aluminum alloy dies casting parts are effective measures to prevent cold cracking of aluminum alloy die castings due to shrinkage stress.

The sand mold and sand core of large aluminum alloy die castings can be excavated in advance after pouring, to reduce their shrinkage resistance to aluminum alloy die castings and promote the uniform cooling of all parts of aluminum alloy die castings. Collision and extrusion shall be avoided during sanding, cleaning, and handling of aluminum alloy die castings to prevent cold cracks of aluminum alloy die casting parts.

-

Aging heat treatment

Aluminum dies casting parts with large casting stress shall be subject to aging heat treatment in time to avoid cold cracks caused by excessive residual stress. If necessary, aluminum alloy dies casting parts shall be subject to one-time aging heat treatment after cutting pouring riser or welding repair.

We are leading and professional aluminum dies casting parts manufacturers, we can supply Precision Casting Parts, if you need help, plz feel free to contact us.